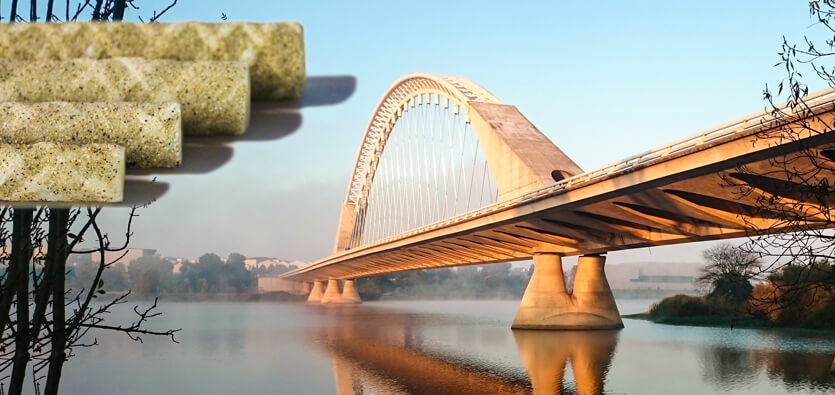

A construction material must adapt to the culture and demands of civil engineering community in order to be successfully implemented. FRP composites, undoubtedly, have gained considerable acceptance and popularity in bridge engineering. How can advanced composite materials (FRPs) address the longstanding deterioration problems associated with highway infrastructure?

We know that bridges and waterside concrete structures have been deteriorating for many years. The ongoing rehabilitation process is very expensive, however, necessary to keep the existing structures in an operational condition. The FRP composites have turned out to be potential reinforcement materials that can help the construction industry eliminate deterioration related problems permanently and achieve long-term objectives in a cost-effective manner.

The worldwide highway infrastructure is subject to severe environmental conditions, corrosion of steel beams, heavy loads, wrong maintenance practices, etc. It is an established fact that conventional materials cannot satisfactorily meet the public need for durable structural components, rapid construction, and inexpensive maintenance. The construction industry needs FRP composites more than ever because FRP’s strength meshes with the shortcomings of widely used traditional materials. Following are some of the major bridge design objectives and techniques to achieve these objectives:

1. Safety comes first

Constructing safe infrastructure must be the top priority of bridge designers. Bridge collapses occur but they are absolutely unacceptable. A large amount of taxpayers’ money is allocated to build and maintain safe public infrastructure. FRP composites have been studied and tested extensively in terms of safety of durability. The result demonstrates that, if implemented and designed properly, FRP can exhibit strength in excess of what is required.

2. Serviceability

Researchers have carried out extensive accelerated laboratory durability tests to determine whether or not FRP composites are capable to withstand harsh highway bridge environment. The result showed that FRP technology has the potential to provide bridges with adequate durability and strength both in new and rehabilitation applications.

3. Constructability

There is no doubt that FRP is an inherently lightweight material. Advanced composites such as GFRP rebar offer high strength-to-weight-ratio which makes the fabrication and erection process smooth without additional stress and difficulty. We know that the ease of construction and transportation can minimize production cost of a project and enable engineers to complete a project quickly without causing indirect social costs.

4. Economy

In some cases, it become difficult to achieve economical bridge designs with advanced composites. The initial high cost of FRP reinforcement and competitive bidding process make it difficult to construct FRP-reinforced highway bridges without subsidy. This is probably one of the main reasons why composite materials are still struggling to dominate the rebar market. It is important to consider that factors such as ease of construction, improved durability, and low life-cycle costs offset the initial high cost of FRP components.

There are some other bridge design objectives which include inspectability, deformation, and aesthetics. Conclusively speaking, FRP composites such as GFRP fiberglass rebar have the potential to meet and exceed the requirements and expectations of the construction industry.

About TUF-BAR

At TUF-BAR, we develop and produce the highest-quality fiberglass rebar and accessories which are stronger and lighter alternative to conventional steel products. Our focus is to produce construction products that can extend the life of concrete structures up to 100 years without spending heavily on maintenance activities. Feel free to discuss your project with us!