Portland cement concrete is world’s most widely used construction material because of its incredible durability. However, factors such as material limitations, construction practices, and severe environmental conditions can lead to concrete deterioration and structural problems. Concrete deterioration is associated with a number of reasons. Salt-induced reinforcing steel corrosion in concrete structures, for example, is one of the major reasons why construction and transportation agencies have to spend billions of dollars every year to rehabilitate the corroding concrete infrastructure.

1. Deicing-salt corrosion

The massive spreading of salts on roadways, airport pavements, and other transportation concrete structures is one of the reasons of concrete deterioration. The use of sodium chloride, calcium chloride, and magnesium chloride has increased considerably over the past few years. These salts absorb moisture from the air and become extremely corrosive once a certain level of humidity and temperature is achieved. Apart from environmental concerns, the excessive use of deicing salts are criticized for it contributes to corrosion of steel reinforced concrete.

2. Freeze-Thaw cycles

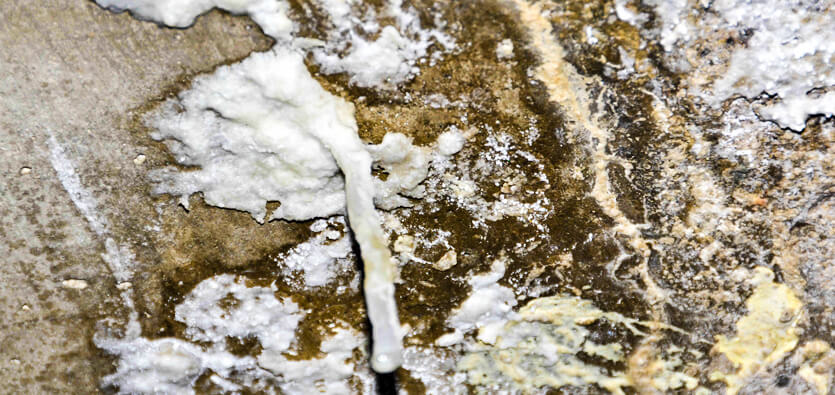

Reinforced concrete structures are simultaneously subjected to various physical and chemical attacks. Freeze-thaw induced deterioration is also one of the reasons why concrete cracks and loses its strength. When water freezes, it expands and the frozen water concentrated inside the concrete produce pressure in pores and capillaries. The cavity will rupture and dilate when the pressure exceeds the tensile strength of concrete. The accumulative effect of successive freeze-thaw cycles will eventually lead to expansion and crumbling of the concrete.

3. Corrosion of the steel reinforcement

The leading cause of deterioration in most of the structurally deficient bridges is the corrosion of steel reinforcement. The conventional materials like steel cannot withstand the harsh corrosive agents and thus require perpetual maintenance and rehabilitation which ultimately increases the cost of a project in the long run. To permanently eliminate the problems associated with reinforcement corrosion, researchers and structural engineers have developed FRP materials which are corrosion-free and superior in terms of strength.

Related: The effects of corrosion on the service life of reinforced concrete structures

Solution

Fiber reinforced polymers are non-metallic materials which do not corrode. The adoption of emerging construction materials and techniques such as GFRP fiberglass rebar, adequate concrete cover, good design and construction practices can dramatically reduce corrosion related problems. Fiberglass rebar is now being used increasingly as an alternative to conventional steel bars.

TUF-BAR strives to produce and deliver corrosion-free and environment-friendly construction materials including fiberglass bars, rock bolts, concrete lifting anchors, and form ties in North America. Our rust-free fiberglass rebar is designed to enable concrete structures successfully bear heavy loads and harsh environment for more than 100 years with almost zero maintenance.